Test Jig Examples

Categories:

4 minute read

We’ve collected a series of methods different groups have used to solve their testing and production woes. The following is a curated list of interesting examples we’ve found. Let us know about how you’ve solved this problem before!

Fork & NOTA

Fork is a data acquisition system spun out of the production of the NOTA project. This is a great write-up of their methods and materials all the way from the requirements resolution through setting the testers up with their contract manufacturer.

They use the ubiquitous orange phenolic test chassis with a designed in-house cassette. They’ve got all the parts you need to reproduce their jig and a guide to customizing it available.

Bunnie Huang / Bunnie Studios

Bunnie Huang has write-up on his experience with DIY jigs for badge testing and updates, production in china, etc. If you’re interested in hardware hacking his book Hacking the Xbox is fantastic, highly recommend. This is one of if not the most detailed write-up we’ve seen publicly available. He includes the entire process he went through including examples of several jigs and a software suite he wrote called Exclave which is on GitHub here.

LabJack & ThermoDart

Labjack is a great company that’s worth your attention. We’ve used their T3 and U3 systems in several jigs and one off projects. They’re robust, reliable, and simple which is a great fit for many applications.

This article was written by the engineers at ThermoDart to show case their in-house testing solution and programming solution. Unfortunately it appears that ThermoDart has closed its doors for good.

Electric UI

Electric UI has some nice hardware-in-the-loop (HIL) support focused on development boards. Their write-up is a good read on testing several common arduino boards with several common USB-serial adapters with MAC, Windows, and a few Linux flavors. They ended up building a single mega-board that can connect all the different serial adapters to all the different boards which is pretty neat.

Adafruit

This guide from Adafruit shows the process they used to build a production tester for their Stemma GPS module board.

The jig they make is an Arduino shield with R75 type ATE probes and a stack of 2x PCBs. Interestingly they leave out the socket and solder the ATE tip down directly. True to form they have all the tools and parts required available from their store.

Dygma Labs

Dygma documented their manufacturing and design journey THOROUGHLY. They have a huge number of war stories including all the things they wished they knew before starting. If you’re starting down the hardware start-up route it’s worth reading through their story.

- Explaining what a test jig is and why we need it: 2018-07-18

- Mass production status: Ongoing: 2019-10-07

- Tales From The Factories: 2019-11-04

- Tenting, manufacturing, and Limited Deilor Edition ergo keyboards: 2020-05-18

- We’ve assembled the first 100 Dygma Defy!!: 2023-06-13

OpenFixture

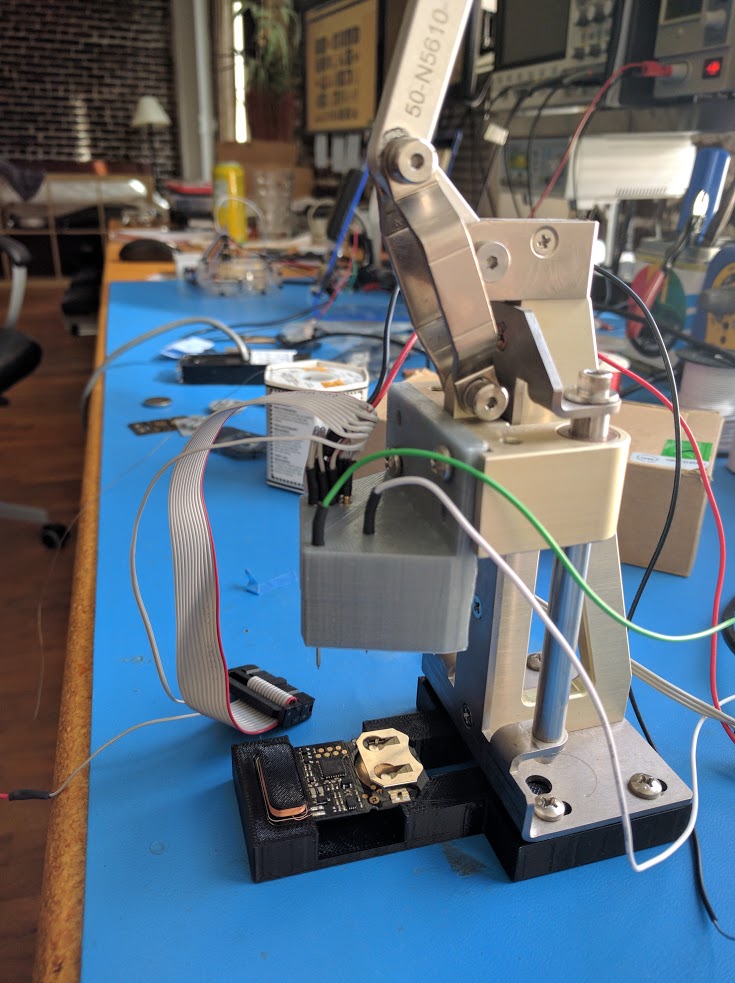

OpenFixuture is also a parametric jig system similar in character to TheJigsApp. The project is fully open source (CC License) and comes with a full suite of tools for exporting from KiCAD. The main branch hasn’t been updated since 2017 but there’s another branch that has had some recent contributions here. Their linkage mechanism is particularly interesting:

TinyLabs.io Test Jig

Opulo & LumenPNP

Core Electronics

Core Electronics is an Australian electronics store focused on makers with in-house production.

Source Electronics

Solid article on how they’ve built jigs for a whole line of products. Includes a list of parts, reasons you’d want a jig, and a few examples of what to test.

Strange Parts: PCBWay Factory Tour

The link starts at the functional test jig introduction but the whole factory tour is great. There’s not a ton of content on testing specifically but visuals are always nice.

MagicDAQ & Robert Feranec

Solid video walk-through of the MagicDAQ platform and a bunch of jig examples. MagicDAQ is worth checking out as a potential component in your test engine.

Flipper Zero

The Flipper zero has been one of the more talked about bits of kit recently for no small reason. For all its functionality they’ve had a reputation of just working every time (this can’t always be said for new ambitious products). They show you exactly what they built and how their process went in one of the most detailed descriptions I’ve seen.

Hackaday Supercon Badges

Production process of the 2017 Hackaday Supercon badges. These are done with a built-in self-test (BIST) which is a great method if you can do it. As a sole method it does have some down sides which are discussed. One thing to keep in mind with BIST is the added hardware cost, development time, and (crucially) more planning. In our design we use BIST whenever possible and whenever there isn’t too high a trade-off with the project goals.