Applications

Categories:

4 minute read

Hardware in the Loop

HIL brings the proven software development techniques of CI/CD to hardware design. Changes made to the software, HDL, or device setting trigger a series of automated tests to confirm functionality and avoid regressions.

Setting up acceptance tests with automated tooling helps teams develop functionality faster without sacrificing reliability or increasing the demands on a QA team. Testing on real hardware with real or simulated stimulus decreases the number of unknowns and therefore the number of headaches and 2 am phone calls.

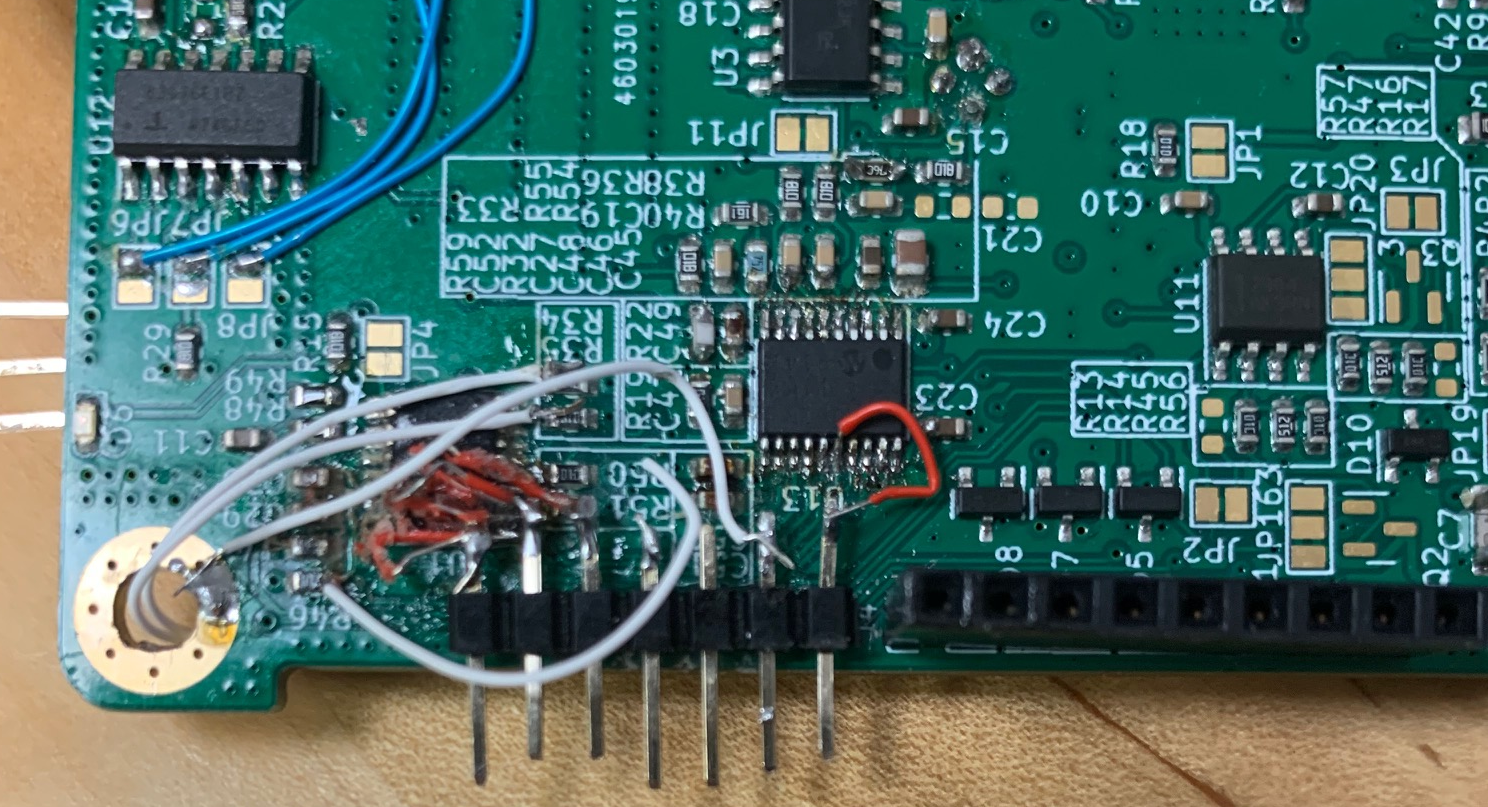

Although it is time well spent, setting up a HIL system is a project in itself. With today’s shrinking PCB sizes and the push for fewer component counts it’s often difficult to make all the desired connections to a device under test (DUT). This can be done by hacking: soldering wire-wrap wire to nets that don’t have connectors and gluing it all down or by using a carefully set up probe station. Not only do these methods work, despite their flakiness they’re usually the best first step. There’s a good example of this process here.

Development hacking badges

As a full disclosure here’s one of my earlier struggles:

Development hacking sensors

Once you have hardware that isn’t changing every day, your system can be made more rugged and much more reliable by using a jig. Because there’s no need to change the unit you’re testing often, jigs for HIL testing are typically slightly different from production jigs. Otherwise there is no fundamental difference.

Manufacturing Functional Test

The traditional home of test jigs is at the end of a manufacturing line. Test jigs at the factory help detect defects quickly, allowing a tight feedback loop to fix issues. Our jigs are familiar sights at both small in-house production houses and CMs. Say your team has made a new IOT product. With our made-to-measure jigs, you can ensure that the boards you receive are programmed and fully tested by the time you receive them. Forget having to deal with fallout by having the problems fixed immediately when they arise.

Our jigs are easily serviced and operated by third parties which allows a streamlined process for setting up factory testing.

Because they’re so cost-effective, it’s also natural to keep a spare jig or two at the CM to avoid the possibility of expensive downtime and production delays.

sequenceDiagram

autonumber

participant tja as The JigsApp

actor bd as Board Designer

Note right of bd: PCBA Design

bd->>tja: Orders Jig

activate tja

tja->>bd: Ships Jig Kit(s) (>14 days)

deactivate tja

destroy tja

activate bd

Note right of bd: Assemble Kit(s) (Approx. 30 minutes)

Note right of bd: Assemble & Verify Testing Electronics

deactivate bd

create actor cm as Contract Manufacturer

bd->>cm: Send Jig

activate cm

Note right of cm: Programming, end of line testing, & functional test

deactivate cm

destroy cm

cm->>bd: Tested & programmed boardsThe Role of a Test Jig in Manufacturing:

Quality Assurance: By subjecting electronic devices to rigorous and repeatable automatic testing using test jigs, manufacturers can identify and address defects early in the production process, catching issues quickly before they become expensive.

Efficiency and Throughput: Test jigs automate the testing process, reducing the time and labor required for manual testing and improving repeatability and consistency. This results in increased throughput, higher quality, and a faster time-to-market.

Cost Savings: Investing in a test jig early on can lead to significant cost savings by minimizing the risk of product recalls, warranty claims, and field failures. Production can be quickly scaled with our under two week turn-time saving factory time and increasing line efficiency.

Development Jig

When developing software for a new embedded device you need access to far more nodes than you will ever actually pin out. Being able to easily place a scope, function generator, logic analyzer, debugger, etc. on the node you want can save a ton of time. Although essentially identical to a HIL jig there’s one exception: you rarely have a jig when bringing up a board. Even if you are building a production and HIL jig it is rare for teams to invest the required time in getting a jig made for board bring-up. Bring-up and system integration are when the weird bugs shown up, often causing schedule slippage.

With our system you can have a made-to-measure jig delivered at the same time as your boards speeding up board bring-up and time to market. Get schedule time back when you need it most!

Others of Note

- Calibration & Personality Station

- Programming Station

- Manufacturing In-Circuit Test

- Refurbishing & Failure Analysis